A Practical Guide to Linished Stainless Steel

- 11 minutes ago

- 9 min read

Linished stainless steel has a clean, uniform grain running in one direction. It is created using a controlled abrasive process.

This finish is excellent at hiding minor scuffs and daily wear. It is a smart choice for high-traffic areas like lobbies, lifts, and corridors.

Understanding how to care for it protects your building's assets and saves money on repairs.

What is a Linished Finish?

A linished finish is made with abrasive belts. These belts create fine, parallel lines across the steel.

The result is a satin-like, non-reflective look. You see this finish on lift doors, escalator panels, and handrails.

Its main purpose is to hide fingerprints, minor scratches, and smudges. These marks would be very obvious on a shiny mirror finish.

Why the Grain Direction Is Critical

The "grain" is the most important feature of linished stainless steel. Think of it like the grain in a piece of wood.

All cleaning and maintenance must follow this direction. Wiping against the grain causes damage.

When you scrub against the grain, you push dirt into the tiny grooves. This makes the surface look dull and can cause permanent scratches.

For facilities managers, enforcing the "clean with the grain" rule is the best way to prevent damage. This simple step extends the life of your stainless steel assets and prevents costly restoration. Incorrect cleaning is a common mistake that degrades valuable assets.

Stainless steel is not rust-proof and needs proper care. You can learn more about different surfaces in our guide to stainless steel finishes.

Key Features for Asset Managers

Knowing the benefits of a linished finish helps you make better maintenance decisions.

Durability: It is designed for busy areas like shopping centres and train stations.

Easy Maintenance: When cleaned correctly, it is simple to maintain. This lowers long-term cleaning costs.

Professional Look: It provides a clean, modern appearance without constant polishing.

Understanding linished steel helps protect your investment. Early maintenance is always cheaper than fixing major damage later.

Linished Steel vs. Other Common Finishes

Not all stainless steel finishes are the same. Treating every surface the same way can cause expensive damage.

A shiny mirror finish looks great but shows every fingerprint. A linished stainless steel finish is a workhorse, designed to hide minor scuffs.

Recognising these differences is crucial for asset managers. It protects your property, helps you budget for care, and stops small cleaning mistakes from becoming big problems.

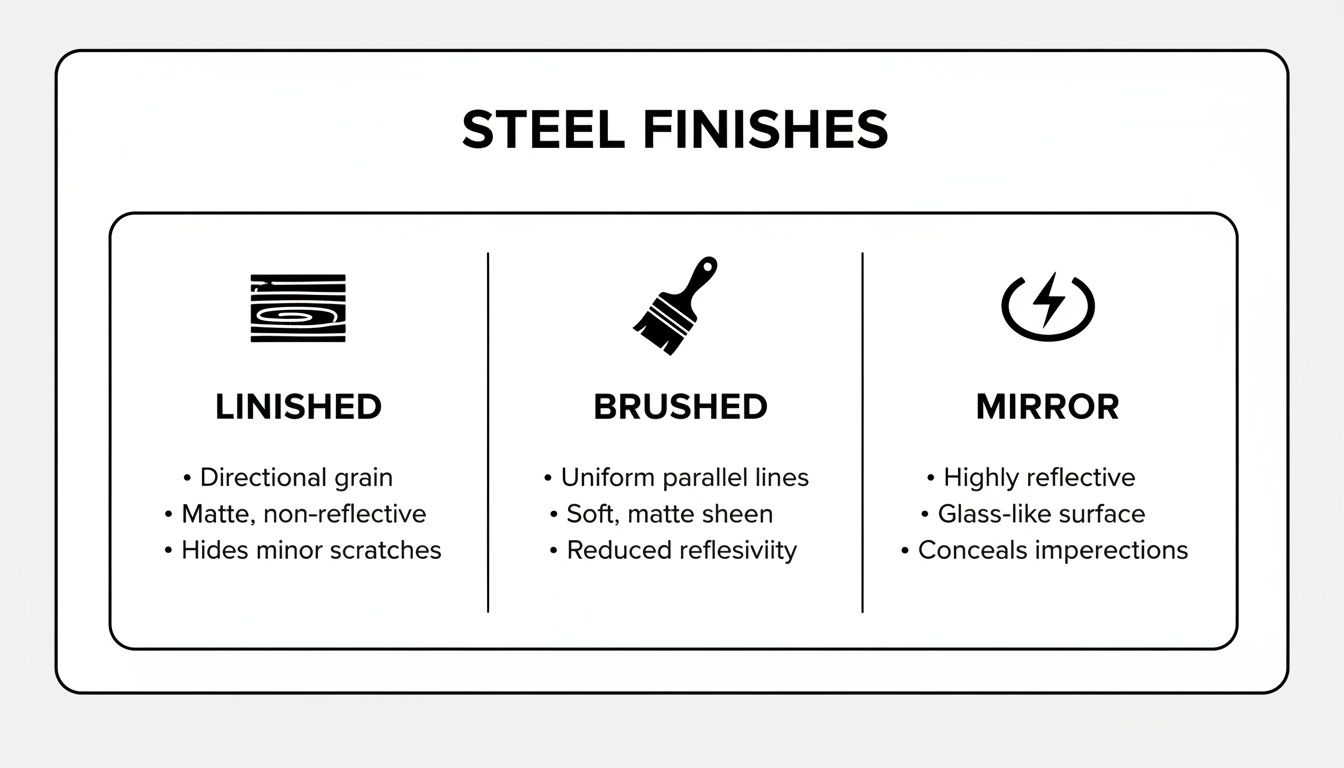

Linished vs. Brushed vs. Satin

People often confuse the terms "linished," "brushed," and "satin." They look similar from a distance but have different textures and need different care.

Linished Finish: Has a clean, uniform grain with distinct parallel lines. It hides minor scratches well, making it ideal for lift doors and kick plates.

Brushed Finish: Also has a directional grain, but it is often coarser and less defined than a linished surface.

Satin Finish: A smoother option with very little shine. The grain is less obvious. It's easy to clean, making it common in kitchens and medical facilities.

Proper care starts with knowing the finish. You can learn more with our information on stainless steel polishing services.

The High-Maintenance Mirror Finish

A mirror finish (No. 8 finish) is the most reflective and smooth option. It is polished until all imperfections are gone, creating a glass-like surface.

It looks impressive but is very hard to maintain in a busy area.

Every touch leaves a fingerprint or smudge. Even tiny scratches are easy to see, requiring constant cleaning. This makes it a poor choice for high-traffic zones.

Using the wrong cloth can permanently scratch the surface. This leads to expensive professional restoration bills.

The popularity of stainless steel is growing. Australia's stainless steel cookware market is expected to reach USD 560.8 million by 2030. Learn more about the Australian stainless steel market.

A Quick Comparison for Managers

Knowing your finish is key to the right cleaning plan. This table helps you identify steel assets and understand their needs to prevent costly mistakes.

Finish Type | Visual Look | How It's Made | Main Challenge |

|---|---|---|---|

Linished | Uniform, directional grain. | Abrasive belts create parallel lines. | Wiping against the grain traps dirt. |

Brushed | Visible lines, often coarse. | Wire brushes or abrasive belts. | Traps dirt if not cleaned with the grain. |

Satin (#6) | Soft sheen, very fine grain. | Fine abrasive polishing. | Abrasive cleaners will damage the surface. |

Mirror (#8) | Highly reflective, glass-like. | Multi-stage fine polishing. | Shows every fingerprint and scratch. |

Identifying each finish helps your cleaning teams use the right methods. This preserves the look and life of your stainless steel assets.

Where to Find Linished Finishes in Commercial Buildings

You will find linished stainless steel throughout any modern commercial building. Architects choose it for its professional look and durability.

These surfaces are valuable, long-term assets. For a facilities manager, knowing where they are used is the first step to a cost-effective maintenance plan.

Lifts and Escalators

Lifts and escalators are the most common places for linished steel. Lift doors, interior walls, and button panels get constant use.

These areas are touched, bumped by trolleys, and scraped by bags.

The directional grain of a linished finish is designed to hide these minor scuffs. It keeps the area looking clean without the need for constant polishing. You will also find it on escalator side panels and balustrades.

Architectural Features

You will also see linished steel used for many architectural elements.

Wall Cladding: Creates a modern, tough surface in lobbies and corridors.

Column Surrounds: Protects structural columns from impact and adds a sleek look.

Kick Plates: Found at the bottom of doors to absorb impacts from feet and carts.

Skirting and Trims: Provides a hard-wearing finish in public spaces.

In 2023, Australia produced 5.4 million metric tonnes of crude steel and imported another 6.6 million. This shows how vital it is to have local experts available to restore and maintain these materials. You can learn more about Australian steel market and its trends.

Knowing where these surfaces are helps you schedule the right cleaning. It also tells you when to call a stainless steel cleaning service before minor issues become major expenses.

Common Causes of Damage to Linished Steel

Stainless steel is tough but not invincible. Most damage to linished surfaces is preventable.

It usually comes down to incorrect daily cleaning routines.

Understanding these common causes helps protect your assets and avoid expensive restoration. Preventative maintenance is always cheaper than reactive repairs.

The Wrong Cleaning Chemicals

Using the wrong chemicals is a fast way to ruin linished stainless steel. Cleaners that are acidic, alkaline, or contain bleach will attack the steel's protective layer.

This leads to discolouration, pitting, and even rust.

A common mistake is using harsh bathroom cleaners on lift doors. These products can strip the finish, leaving permanent streaks.

Always use pH-neutral detergents. They clean effectively without causing chemical damage that degrades the steel.

Abrasive Tools and Wiping Against the Grain

The tools used for cleaning are as important as the chemicals. Steel wool, scouring pads, and gritty sponges are too aggressive for a linished finish.

They create fine scratches that trap dirt and dull the surface.

The biggest mistake is scrubbing against the grain. Wiping in circles or across the grain pushes dirt deep into the grooves. This makes the surface look dirty even after cleaning.

Abrasive Pads: Create micro-scratches that cause a hazy look.

Scrubbing Against the Grain: Pushes dirt into the finish's fine lines.

Hard-Bristled Brushes: Can easily scratch and mar the surface.

Environmental Factors

The environment affects your stainless steel assets. Airborne particles and moisture can cause damage even without direct contact.

For coastal buildings, salt is the biggest threat. Chlorides in the sea air can cause "tea staining," a brown discolouration. Our guide explains why even stainless steel can rust.

In urban areas, pollutants and iron particles can also cause damage. Regular, correct cleaning is the only way to prevent this.

Physical Damage

Physical damage is a constant risk in busy commercial spaces. Scuffs, dents, and deep scratches are common.

Impact damage often comes from:

Luggage and trolleys bumping into lift walls.

Equipment moved without care.

Scuffs from shoes on kick plates.

While some wear is expected, significant damage harms the asset's look and integrity. This shows why it is important to treat these surfaces as investments that need protection.

How to Clean Linished Stainless Steel Correctly

Protecting your linished stainless steel starts with a simple, consistent cleaning routine. Giving your team the right instructions prevents small mistakes from becoming expensive problems.

The goal is to clean the surface safely without causing new damage. Incorrect cleaning is the top cause of premature wear.

The Correct Daily Cleaning Process

Follow this simple, three-step process for routine cleaning. This method is safe for linished surfaces and prevents grime buildup.

Use the Right Cleaner: Mix a pH-neutral cleaner with warm water as directed. Avoid any products with bleach, ammonia, or acids.

Wipe With the Grain: Dampen a soft microfibre cloth. Always wipe in the direction of the steel's grain, never against it. This lifts dirt out of the grooves.

Rinse and Dry: Use a second clean, damp cloth to rinse away cleaner residue. Dry the surface completely with a dry microfibre cloth, wiping with the grain to prevent water spots.

This simple method is all you need for daily maintenance. It keeps your linished steel looking professional without causing harm. For more detail, see our guide on the best practices for cleaning stainless steel.

When to Call a Professional

Knowing when to stop is as important as knowing the right technique. Trying to fix deep damage yourself almost always makes it worse.

DIY methods are for cleaning, not repair. If you see deep scratches, rust, or widespread discolouration, it's time to call a professional. A specialist can restore the surface correctly.

Trying to buff out a deep scratch with an abrasive pad will ruin the uniform grain. This creates an ugly blemish that is very noticeable.

Signs You Need Expert Help:

Deep Scratches or Gouges: Marks from trolleys or equipment.

Widespread Discolouration: Large brown 'tea staining' patches or dark blotches.

Visible Rust Spots: Any orange or brown corrosion means the protective layer is broken.

Hazy or Dull Appearance: A cloudy look that cleaning doesn't fix.

Calling a professional for these issues is the most cost-effective solution. It prevents minor damage from becoming a full panel replacement. Proper lift restoration saves the asset and avoids significant costs.

Professional Restoration for Damaged Linished Steel

When damage to your linished stainless steel is beyond a simple clean, professional help is the smartest choice. Trying to fix deep scratches or rust yourself usually makes the problem worse.

This turns a simple repair into an expensive mess.

Replacement is the alternative. It is costly and causes major disruption. On-site professional restoration returns the steel to its original state for a fraction of the cost and with minimal downtime.

The Restoration Process

Professional restoration is a careful, multi-step process. It requires special equipment and an understanding of the metal's original finish.

The goal is to perfectly match the original grain.

Assessment: A technician inspects the damage to understand its depth and the exact grain of the finish.

Re-Graining: Using special tools, the specialist works with the grain to remove the damaged layer and restore the clean, uniform lines.

Blending: The restored area is blended into the surrounding surface to make the repair invisible.

This image shows the difference between a damaged and a professionally restored surface.

The restored section on the right perfectly matches the original finish. This proves that even significant damage can be reversed, saving a valuable asset from being replaced.

Protect Your Restored Steel

Restoring the steel is the first step. Applying a protective coating is the next crucial step.

This clear coating acts as a barrier. It absorbs scuffs, scratches, and corrosive elements, shielding the steel underneath. Learn more from our guide to stainless steel scratch removal.

A protective coating is an effective way to extend the life of a steel asset. It reduces cleaning needs, protects against damage, and delays future restoration.

Why Restoration and Protection Saves Money

For any facilities manager, decisions are based on cost, durability, and risk. Professional restoration and protection is the best choice for all three.

Saves Money: Restoration is much cheaper than replacing an entire lift door or panel.

Prevents Future Damage: A protective coating acts like insurance against daily wear and tear.

Reduces Downtime: On-site restoration is faster and less disruptive than a major replacement project.

Extends Asset Life: A properly maintained and protected surface lasts years longer.

Choosing professional restoration is a strategic decision. It protects your budget, preserves your building's appearance, and extends the life of your most visible assets.

Your Questions About Linished Steel Answered

Here are direct answers to common questions from facilities managers and building owners.

Can deep scratches be removed from a linished finish?

Yes, most deep scratches can be removed completely. Professional restoration uses specialised equipment to resurface the steel and replicate the original grain.

This process makes the repair invisible.

It is far more cost-effective than replacing an entire panel. Trying to fix deep scratches yourself will likely create a bigger, more obvious blemish.

Is linished stainless steel good for coastal areas?

Yes, but only if you use the right grade of steel. For outdoor use in coastal areas, you must use Grade 316 stainless steel.

Grade 316 contains molybdenum, which increases its resistance to salt corrosion.

Grade 304 is suitable for indoor use but will rust quickly when exposed to salty air. All steel in coastal locations needs frequent cleaning to remove salt deposits. A professional protective coating is also recommended.

How often should linished steel be professionally maintained?

It depends on the location and amount of use.

High-Traffic Areas: Lift doors or shopping centre balustrades should be assessed every 6 to 12 months.

Medium-Traffic Areas: Corridor panels or office lobby features need an inspection every 12 to 18 months.

Low-Traffic Areas: Surfaces with little contact can be checked every 18 to 24 months.

A professional site assessment will provide a custom maintenance schedule. This prevents costly damage before it starts.

Is restoring linished steel cheaper than replacing it?

Yes, absolutely. On-site restoration is significantly cheaper than replacement. It often saves between 70% and 90% of the cost.

Replacement involves material costs, demolition, installation, and major disruption. Restoration is done on-site, minimises downtime, and returns the asset to its original condition for a fraction of the price.

When daily cleaning is not enough, Steel Renew protects your investment. We restore damaged linished stainless steel, extending its life and helping you avoid the high cost of replacement.

Request a site assessment to get professional advice on your asset maintenance plan.

Comments